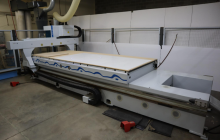

2012 Biesse Skipper V31 Vertical Machining Center

| MA ID: | RC3 - 11715 |

| Status: | Sold |

| Price: | $27,900.00 |

| Category: |

CNC Router (3-axis)Point to Point |

| Manufacturer: | Biesse |

| Model: | Skipper V31 |

| Year of Manufacture: | 2012 |

| Condition: | Very Good |

| Electric: | 230 Voltage 60 Cycle 3 Phase |

|

Specifications:

CNC panel machining centre - ‘X’ working field 2500 mm, ‘Y’ working field 900 mm. The machine is equipped with 10 vertical independent spindles, 6 horizontal independent spindles and a grooving saw unit in ‘X’ direction (BH17).

(min.-max. dimensions) Length - X 200 - 2500 mm Width - Y 70 - 900 mm Thickness - Z 10 - 70 mm Working table height from floor: 700 - 750 mm

In order to guarantee the operator’s safety the machine is equipped with a protection system by carters to restrict the access to the working area. The system is in conformity with the safety requirements of the EC regulation 2006/42/EC.

The machine bed is made by a vertical beam on which the operating unit with independent spindles is installed, an horizontal beam on which the positioning group for the panel X movement and the supporting worktables are installed.

Slidings on prismatic guides and recirculating runners for X, Y and Z axes. The vertical and horizontal beams are both equipped with a rack with inclined teeth for a high-precision transmission by grinded pinion.

The machine is equipped with a positioning group for the panel X movement by a pneumatic gripper. The group is installed on the horizontal beam (max. stroke 1000 mm), it is started by the numerical control and is managed by automatic multiple positionings of the gripper to guarantee all the panel workings.

The panel pre-positioning in X direction (lengthwise positioning) is performed on the machine LH area and it takes place through 1 stop placed in fixed position on the LH side of the main worktable; a laser photocell automatically reads the X panel reference (origin); in addition the same photocell measures the real panel length. The panel reference in Y direction is performed on a bottom roller way.

The operating unit is composed of 10 vertical independent spindles, 6 horizontal independent spindles and 1 grooving saw unit diameter 120 mm. The configuration of the operating unit is the following:

Main specifications:

The operating unit is prearranged for the installation of the electrospindle.

The main worktable is fixed and positioned in the centre of the machine supporting the panel during the working operations; the worktable structure is particularly rigid and its surface is covered by material with the lowest friction factor. The sliding tables, the LH loading table and the RH unloading one, are both equipped with rollers for the panel lengthwise X movement. The tables are inclined of 5 deg. to allow an ergonomic and safe loading operation.

The machine control and management are made up by a PC equipped with a new generation Control PC system. The PC and the control board are installed on the machine front side, in an ergonomic position for the operator. A high-level software interface makes particularly easy and direct the machine programming and allows:

* DESKTOP PERSONAL COMPUTER with colour display LCD 19". Operating system Windows XP Professional. PC specifications as per current standards on the market. * The technical data of the description can be subject to changes.

It allows an immediate and direct access to the machine numerical control. In this way it is possible to check machine data, user’s programs, input/output signals and system variables, and to install software updates. It includes: - Ethernet connection card; - The teleservice support is free of charge for the whole warranty period.

The electric cabinet is placed on the front of the machine bed. This solution avoids floor cables guaranteeing the easiest access to the machine and the maximum cleanness around the machine.

Transformer and electronic power supply unit for voltage 380 - 415 V (+-10%), 50/60 Hz.

- User’s manual; - Manual for controller unit programming; - Pneumatic and wiring diagrams; - Spare parts catalogue 7570075 TRANSFORMER for voltages different from 380/400/415 V - 50/60 Hz 7212811 4.5 kW (6 HP) electrospindle with ISO 30 adaptor, air cooled - Controlled by Inverter. Main specifications:

26451 RH TOOL-HOLDER WITH ISO 30 ADAPTOR ERC 32, RH rotation Equipped with ring nut. * For tools with cylindrical adaptor with dia. ranging from 6 to 20 mm. * The collet is not included. * Max. rotation speed: 24.000 rpm 26452 LH TOOL-HOLDER WITH ISO 30 ADAPTOR ERC 32, LH rotation. Equipped with ring nut. * For tools with cylindrical adaptor with dia. ranging from 6 to 20 mm. * The collet is not included. * Max. rotation speed: 24.000 rpm 3407070 ELASTIC COLLET Diam. 12-11 mm. To be used only with ISO 30 cones ERC 32. The collet complies with din 6499 regulations. 3407067 ELASTIC COLLET Diam. 20-19 mm. To be used only with ISO 30 cones ERC 32. The collet complies with din 6499 regulations. 7570046 AIR CONDITIONER for electric cabinet, to protect the electric and electronic components from dust and in case the machine works in environments with a temperature higher than 45°C (113° F). 7510011 Manual Reading Laser Device for barcode labels WI-FI connection to the machine NC

7530360 BIESSEWORKS - Advanced programming system - office version (2 hardware keys). It requires the operating system Windows XP. The graphic interface, fully compatible with the Windows standard, grants the following functions:

BiesseWorks Advanced also includes:

Min. PC requirements: - Pentium processor 2 Ghz or equivalent. - 512 Mb RAM (1 Gb advised). - 1 Gb of free disk space. - graphic card with at least 128 Mb of RAM advised. |

|

| Shipping Footprint: | 7' (length) x 8' (width) x 9' (height) |

| Weight: | 3500 lbs |

Please confirm all data before committing to a purchase.

*Subject to credit approval. Additional programs available.