Makor Start-One M Spray line with Loading and Unloading

2018 Makor System. Loaded with the goodies!!

| MA ID: | FLA - 12316 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Status: | Sold | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Price: | Call for Price | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Category: |

Systems & Automated Lines |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Manufacturer: | MAKOR | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Model: | Start One M | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Year of Manufacture: | 2018 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Condition: | Excellent | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Electric: | 480 Voltage 60 Cycle 3 Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Hours on meter: | 1100 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2018 Makor Start-One M Finish Spray Line

Reciprocating Spray Machine START-ONE M Flexibility, reliability and ease of use, combined with limited operational cost and investment, enable the START-ONE to be the ideal machine for replacing a manual spray process or for finishing small series of production. The START-ONE can be used for automatic spraying of all types of paint and glue. In a very simple and effective way, it offers all the advantages of much more complex systems: better utilization of coating materials (paint savings = $) uniformity of application and consistent quality increased productivity compared to a manual operator cleaner and healthier work environment

Transport System for Product Carrier Trays

transportation of work pieces is carried out using product carrier trays product carrier trays are transported through the spray machine on two parallel chains equipped with a variable speed drive (inverter)

Product Carrier Trays

carrier trays can be covered with paper or a similar protective material, which is periodically replaced/recovered as needed to extend functional life system is capable of handling two product carrier tray dimensions: 2440 x 1220 x 25mm (96" x 48" x 1") or 4000 x 1220 x 25mm (13' x 48" x 1") carrier tray dimensions provide a useful working area of: 2200 x 1100mm (86-5/8 x 43-1/4") per carrier tray (26 sq. ft.) or 3700 x 1100mm (145" x 43-1/4") per carrier tray (43.7 sq. ft.) carrier tray length and thickness can vary minimally, but width must be precise to enable proper transportation Spraying Group spray system is composed of one oscillating arm with an electronically controlled drive to ensure smooth movement, providing consistent application across the entire working width entire oscillating group is connected to the frame of the machine through pads which guarantee absolute absence of vibrations, resulting in perfect paint quality on the work pieces spray guns are attached to the oscillating arm using a quick-change gun holding plate with quick disconnects to enable fast replacement of spray guns or for switching between coating circuits; one spare holding plate included four (4) guns can be connected to one of three (3) coating circuits three (3) high pressure circuits with recycle for coatings one (1) high pressure circuit without return for solvent coating circuits have return hoses for quick circuit washing and for paint re-circulation standard supply includes two (2) gun holding plates with quick disconnection system to allow fast replacing of the spraying unit Note: Pumps, guns and connection kit are excluded from the supply. Ventilation System spray booth design ensures proper control of air flow, avoiding the dispersion of the overspray to the environment a large dimensioned filter surface area is designed to keep exhausted particular matter (solid paint particles) in compliance with regulations exhaust fan can be adjusted separately to ensure maximum filter efficiency accessibility is permitted from both sides of the cabin for easy maintenance Control System machine is managed by a PLC with a special user interface that displays and manages all functions and working parameters in an intuitive way a series of sensors detect the workpiece dimensions as they enter the machine to control the spray gun activation (optimize consumption of paint) Options Included three (3) high pressure circuits rapid (manual) coating change-over system enables the operator to cease operation on active circuit, flush guns with solvent, activate the next circuit and then purge first circuit while machine is already in operation on the second circuit; composed of: three (3) high pressure coating circuits with recycle (closed-loop) one (1) high pressure circuit for solvent one (1) 5-way manual valve for active circuit selection Technical Specifications

Utility Requirements

Electrical equipment installed according to UL regulations. Voltage supplied must not fluctuate in excess of +/- 5% of its stated value. Voltage must be balanced phase-to- phase and phase-to-ground. Item 2: Automatic Loader/Off-Loader LIFT 2M Makor's LIFT Loader is especially designed for the automatic loading and off-loading of product carrier trays from trolleys to be put into a processing line. The loader has also a manual loading function. Carrier trays are handled only from the bottom to avoid contact with the coated items on the tray, thereby preserving the perfection of the finish. Structure electro-welded steel structure on which there are housed all the characteristic elements, particularly strong for handling mouldings of large dimensions a platform, placed on the ground, serves as a support for an articulated parallelogram system, operated by means of hydraulic power unit, on which a series of retractable arms is mounted the arms with telescopic function, pick up the jig to be processed from the trolley and bring it to the entrance of the line and vice versa a perimeter fence on three sides and an optical-electronic barrier on the front side ensure the safety of the operators

Control Panel main control panel (usually that is integral part of previous spraying machine) managed by PLC and equipped with liquid crystal operator panel complete with protection devices, controls, and diagramed commands to manage the working cycle and the set-up Options Included designed to access trolleys from right and left sides

Technical Specifications

Utility Requirements

Electrical equipment installed according to UL regulations. Voltage supplied must not fluctuate in excess of +/- 5% of its stated value. Voltage must be balanced phase-to- phase and phase-to-ground.

The trolley model 37/P has been designed for storing product specifically for use with the Makor LIFT System. Two (2) trolleys are supplied.

Structure Lateral columns in welded and painted tubular and sheet iron Two (2) outside columns with two (2) intermediate support columns (4 total) Seven (7) load levels; arms covered with U-shaped PVC each level with 230 mm pitch Maximum weight capacity per level 85 kgs (188 lbs) – including customer supplied tray Includes four (4) polyurethane swiveling wheels, diameter 175 mm

Equipment The trolley is equipped with welded side columns and the base is with

Technical Data

Includes 4 Drying Rack carts Includes Pumps, agitators and guns (Orig cost 31,000) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

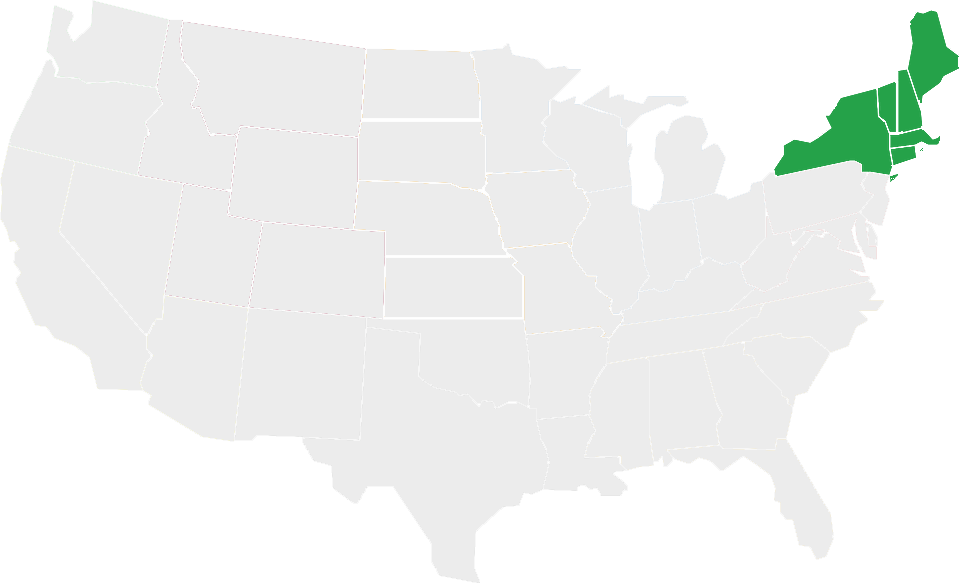

| Rigger: |

Required on selling end

Required on buying end |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Please confirm all data before committing to a purchase.

*Subject to credit approval. Additional programs available.

More Systems & Automated Lines Machines For Sale

More MAKOR Machines For Sale

Makor Start One M ... Factory Video.