Homag KAL500 Edgebander

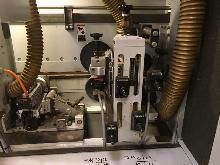

Known as the Homag KAL 500, actual Machine is Homag Optimat KAL 210/5/A3/S2

| MA ID: | EBS - 11191 |

| Status: | Sold |

| Price: | $52,900.00 |

| Category: |

Edgebanders -Single Sided |

| Manufacturer: | Homag |

| Model: | Optimat KAL 210/5/A3/S2 |

| Year of Manufacture: | 2008 |

| Condition: | Very Good |

| Electric: | 480/277 Voltage 60 Cycle 3 Phase |

|

This High Speed Machine can do 25m/min while premilling and corner-rounding. It is a highly desired machine that was on a Stiles maintenance and service program.

Check out the video!

Homag Optimat KAL 500 High Speed Edgebander. RETURN CONVEYOR IS NOT AVAILABLE Technical Specifications Working level; 950 mm (37-13/32") Panel overhang; 30 mm (1-1/8") Feed speed; 18 to 25 m/min (59 to 82 ft/min) Workpiece thickness; 12 to 40 mm (15/32 to 1-9/16") Working width min. 22 mm (7/8") w/thickness; 60 mm (2-5/16") 40 mm (1-9/16") w/thickness; 105 mm (4-1/8") Edge thickness coils only .3 to 3 mm (.012 to 1/8") Processing limits; PVC 135 mm² (.21 sq. in) Veneer 100 mm² (.16 sq. in) Edge coil diameter; 830 mm (32-5/8") Pneumatic connection 7 to 8 bar (102 to 116 psi) Electrical service 480 Volt, 3-phase, 60 cycle

Utility Requirements Electrical Operating voltage 480 V / 3-phase/ 60 Hz Control voltage 24 V Total connected load 49 kW Nominal current approx. 67 A Recommended fuse 80 A

Dust extraction Air velocity (min.) ; 28 m/sec (91.84 ft/sec) Static pressure; 250 mm/ws (9.84"/ws) Air volume; 7040 m³/hr (4143 cfm)

Compressed Air Connection size ¾" Pressure required 7 bar (100 psi) Consumption / volume 825 sl/min (29.12 cfm)

STATIONS Remote Operation for Single-Sided Machines KAL 210 Homag Unit # 0844

Adjustable Infeed Fence

Feed Stepless Adjustable 18 – 25 M/Min

Separating Agent Spray Device Top/ Bottom

Joint Trimming Unit

(4-15/16" x 1-11/16" x 1-1/8"), DKN, z = 2 x 3

Noise Protection

Gluing Unit A3 Consisting of: Workpiece Pre-Heating

Quickmelt Hot Melt Gluing Unit

Magazine Two (2) Coils Manual

Pressure Zone K

Chamfer/ Radius Trimming Unit 0.4 kW

"I" Diamond Radius Cutter R = 3 mm Homag Unit #3585

or 13 chamfer trimming

r =3 mm (1/8")

Profile Trimming Unit FF 12 Top/ Bottom

Front and rear edge with a combination tool

Manual Change and Adjustment Device for FF 12

combination tool

o in case of radius 1.5 mm (0.05") = 0.6 mm (0.024") o in case of radius 2.0 mm (3/32") = 0.8 mm (0.031") o in case of radius 3.0 mm (1/8") = 1.0 mm (1/32")

"I" Diamond Radius Cutter R = 3 mm Homag Unit #3586

or 13 chamfer trimming

Open Space

Scraping Device Profile PN 10

Quick-Change Device for PN10, R = 3 mm Homag Unit #4527

Finish Unit Top / Bottom For finish processing the longitudinal edge. Consisting of: Scraping Unit Glue Joint

Edge Buffing Unit

|

|

| Shipping Footprint: |

26 (length) x 5 (width) x

6 (height)

|

Some photos may show tooling. Tooling is never included in the listing unless otherwise noted in the description.

Please confirm all data before committing to a purchase.

*Subject to credit approval. Additional programs available.

More Edgebanders -Single Sided Machines For Sale

More Homag Machines For Sale

ACTUAL MACHINE DOING DEMO