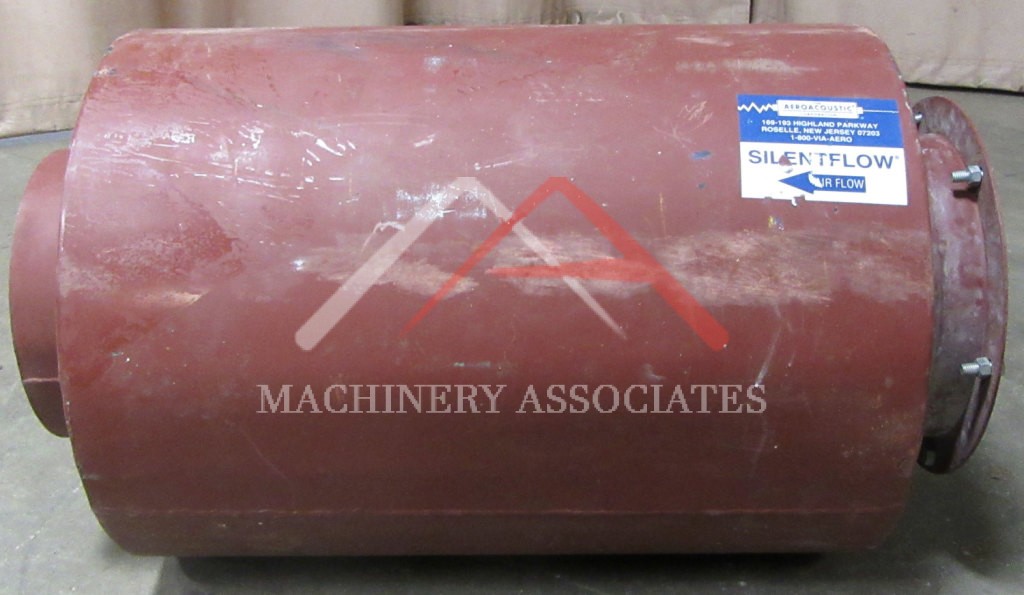

AAON 105 Ton Air Makeup with Heat / Cool

105 ton 27,500cfm air makeup unit with heating and cooling

| MA ID: | FMU - 11997 |

| Status: | Sold |

| Price: | $105,000.00 |

| Category: |

Air M-Up |

| Manufacturer: | Other manufacturer |

| Model: | RN-105 |

| Year of Manufacture: | 2017 |

| Condition: | Excellent |

| Electric: | 460 Voltage 60 Cycle 3 Phase |

|

AAON RN-105 105 ton 27,500cfm air makeup unit with heating and cooling

This unit was purchased new, fully installed and test run at it's current location in 2017 but has never been activated. It has only a few test hours of use on it. Currently installed at ground level on a poured slab, easy access in winter months. Under power and available for inspection 105 ton 27,500cfm Thermostat controlled heating and cooling of supplied air Variable speed Scroll compressors Equipped with AAON Energy Recovery system Direct Drive plenum fans and powered exhaust From AAON: • Cabinet construction consists of rigid polyurethane foam panels with G90 galvanized steel on both sides and a closed cell polyurethane foam interior core. The inner wall protects the insulation from moisture damage, prevents microbial growth, and is easy to clean. |

|

| Rigger: |

Required on selling end

Required on buying end |

Please confirm all data before committing to a purchase.

*Subject to credit approval. Additional programs available.