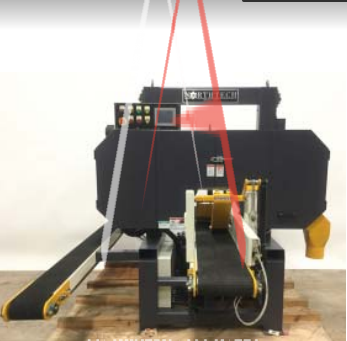

Automatic template band saw

| MA ID: | SBS - 10200 |

| Status: | Archived |

| Price: | $16,800.00 |

| Category: |

Band/Scroll Saws |

| Manufacturer: | OTHER |

| Model: | MZ Project Hopper 013 |

| Year of Manufacture: | 1998 |

| Condition: | Good |

| Electric: | 440 Voltage 60 Cycle 3 Phase |

|

Capacity & Speed: Cuts lengths up to 2,000 mm, max. size workpiece is 2,000 x 1,200 x 100 mm (78.7" x 47.2" x 4"); height of cut is from 0 - 100 mm (0" - 4"); angle cut +/- 45°; dwell (depth of curve) is 150 mm (6"); blade length 5,730 mm (225.6") and a blade speed of 1,550 RPM; forward table speed is 0 - 16 MPM (0 - 52-5 FPM) with return speed of 40 MPM (131.2 FPM). Hydraulic pump cap. is 25 liters and the pump motor is 1,7 kW (2.5 HP) providing working pressure of 40 Bar. Pneumatic working pressure is 6 Bar. Operation: The machine uses a simple template made of laminated wood. The template is located at the rear of the machine. (2) Templates are accepted and are independently controlled by the machine: (1) For the outside cut; the 2nd for the final cut in case the workshape is not symmetrical. -- The template copying device is controlled by pneumatic cylinder, which positions the tracing head into position on the template and withdraws the head when the traveling table, controlled by hydraulic cylinder, returns to the rear start position. -- The tracing head is linked to the band saw blade by means of pivoting arms to the upper-and-lower blade guidance systems. As the template moves forward with the table, the tracing head moves along the template edge twisting-and-turning the vertical blade at the same time the table moves on the pneumatic horizontal cross-transfer and longitudinal movement. -- An automatic feed device is mounted on the upper table and automatically positions the stock at the cutting line after cutting cycle until the stock in finished Equipped with: (2) 150 mm (6") Dia. dust hoods; automatic hopper feeder controlled by electronic positioner to advance the workpiece via ball screw & DC motor; double template device for cutting pieces with (2) profiles, hydraulic copy system, and automatic table speed control Part return system: inclined belt conveyor included to return finish parts back to the operator. |

|

| Shipping Footprint: | 14' (length) x 8' (width) x 8' (height) |

| Weight: | 6000 lbs |

Please confirm all data before committing to a purchase.

*Subject to credit approval. Additional programs available.