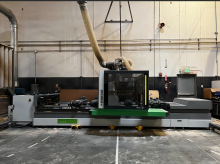

Biesse "Skipper 100" Through-Feed Boring M/C

| MA ID: | BF - 9231 |

| Status: | Sold |

| Price: | $110,000.00 |

| Category: |

Boring - Feed ThroughPoint to Point |

| Manufacturer: | Biesse |

| Model: | Skipper 100 |

| Year of Manufacture: | 2014 |

| Condition: | Excellent |

| Electric: | Multitap Voltage 60 Cycle 3 Phase |

|

Panel Dimensions • Length 90 mm – 3,000 mm • Width 70 mm – 1,000 mm • Thickness 8 (*) - 60 mm (*) If length is more than mm 2.000 the min. thickness increases to 13 mm. Working Fields of the tools (the dimensions refer to tool axis) Length (X) Width (Y) Vertical holes From 0 to 3000 mm From 0 to 1000 mm Vertical Line Boring From 0 to 3000 mm From 32 to 1000 mm Horizontal holes in X From 0 to 2800 mm From 0 to 1000 mm Horizontal holes in Y From 0 to 3000 mm From 90 to 1000 mm Routings (continuous with electrospindles) (partial with electrospindle) From 0 to 2500 mm From 0 to 3000 mm From 0 to 950 mm Grooves (continuous with sawblade) in X (partial with electrospindle) From 0 to 2500 mm From 0 to 3000 mm From 112 to 1000 mm Main Structure The monolithic machine base is made up of thick electro welded steel sheets with structural cross-members precisely located to provide an extremely rigid platform. The machine base is precision processed in a single positioning to achieve the highest mechanical precision. Panel Dimensions • Length 90 mm – 3,000 mm • Width 70 mm – 1,000 mm • Thickness 8 (*) - 60 mm (*) If length is more than mm 2.000 the min. thickness increases to 13 mm. Working Fields of the tools (the dimensions refer to tool axis) Length (X) Width (Y) Vertical holes From 0 to 3000 mm From 0 to 1000 mm Vertical Line Boring From 0 to 3000 mm From 32 to 1000 mm Horizontal holes in X From 0 to 2800 mm From 0 to 1000 mm Horizontal holes in Y From 0 to 3000 mm From 90 to 1000 mm Routings (continuous with electrospindles) (partial with electrospindle) From 0 to 2500 mm From 0 to 3000 mm From 0 to 950 mm Grooves (continuous with sawblade) in X (partial with electrospindle) From 0 to 2500 mm From 0 to 3000 mm From 112 to 1000 mm Main Structure The monolithic machine base is made up of thick electro welded steel sheets with structural cross-members precisely located to provide an extremely rigid platform. The machine base is precision processed in a single positioning to achieve the highest mechanical precision.

|

|

| Rigger: |

Required on selling end

Required on buying end |

All Information including Photos and Videos are supplied by a 3rd party Source.

Please confirm all data before committing to a purchase.

*Subject to credit approval. Additional programs available.

Please confirm all data before committing to a purchase.

*Subject to credit approval. Additional programs available.